How Pre-Fabricated Lighting Distribution Changed The Industry

klik, our original pre-fabricated wiring system celebrated its 30th anniversary in 2014. Stephen Dyson of Hager gives us an insight into how klik came about, how it changed the industry and how the product has undergone a constant evolution since 1984.

In the wake of the industrial disputes of the 1970s, recovery from recession focused the construction industry on controlling rising labour costs and a shortage of skilled labour. In 1981 T8 fluorescent lamps with magnetic ballasts had just been launched in the USA and incandescent lamps were still in wide use. This drove the market to identify new products and Klik, a secure, pre-fabricated and flexible connection system was born. The introduction of the Klik lighting connection system revolutionised how electrical contractors installed lighting.

Giving greater flexibility over fixed wiring, such as speeding up installations and maintenance tasks, Klik delivers up to 70 per cent reduction in labour time compared to a fixed wiring installation. In addition, it meets the contractors need for a safer system, both at initial installation and in facility management throughout the life of the building. As a pluggable lighting connection system, Klik offers on-load disconnection/ connection where the earth terminal makes contact before any other connection and is last to break on disconnection.

Giving greater flexibility over fixed wiring, such as speeding up installations and maintenance tasks, Klik delivers up to 70 per cent reduction in labour time compared to a fixed wiring installation. In addition, it meets the contractors need for a safer system, both at initial installation and in facility management throughout the life of the building. As a pluggable lighting connection system, Klik offers on-load disconnection/ connection where the earth terminal makes contact before any other connection and is last to break on disconnection.

klik Evolution

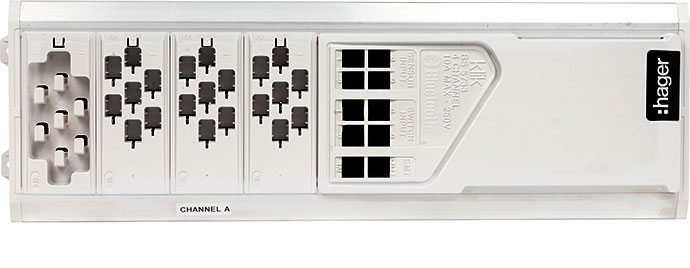

Our development team increasingly noticed that the original standalone pluggable Klik ceiling rose was being used for applications requiring multiple luminaire connections and, through a process of customer feedback and innovative design, the pluggable Klik marshalling box was developed. This product allowed installers to link room lighting from one common point using radial circuit connection, with the pluggable marshalling box giving clients the ability to reconfigure office and retail spaces through the flexibility of the system.Over the last 30 years, there have been several socio-economic and technological changes that have influenced the need for pre-fabricated wiring systems. These changes include digital ballasts, control systems and the introduction of LED lighting, as well as an increase in customer expectation to improve lighting control, changes to building regulations and to enable the trend for digital dimmable ballasts. Since its inception Klik has evolved to meet these changing demands.

To correspond with the advancements in lighting, Klik has evolved from a three-pin system in 1984, to today’s range which includes a seven-pin system that enables switching, control (via KNX, DALI, DSI) and emergency lighting requirements.

Following on from the use of manual wall switch to control the lighting, automatic control was first achieved by installing occupancy sensing into each room/ workspace. Initially designed for sensing presence and switching the lights on and off in response to the sensors, Klik functionality soon allowed absence detection to avoid unintentional switching in applications such as schools.

With the rise of home automation and lighting control driven by the need for efficient energy usage, consumers are more aware of the possibilities digital control can offer, bringing experience at home into the work environment. Lighting can often be the easiest and most cost-effective way to save energy in both residential and commercial facilities.

Commercial Buildings

The primary objective in any type of building is to provide a well-lit and safe working environment, which provides occupants with a feeling of wellbeing and allows them to perform visual tasks (e.g. improved worker satisfaction/ productivity, student performance and retail sales). Lighting should also be designed to enhance a space so that it appears attractive and interesting.

Modern use of office or learning spaces is more diverse, resulting in occupants using them in a variety of ways. Meeting rooms may need to be subdivided or lighting adjusted to certain activities such as presentations or to take account of outside light levels. It is important for installers to find out in the early stages of a project how spaces will be used so that flexibility and efficiency in the lighting system can be designed and specified at an early stage. Good lighting connection and control can further improve installation time, reduce installation costs and enable electrical contractors to do more without increasing labour costs.

New developments

Most lighting designs are split into standard luminaire, digital or a mix of luminaires. New for 2015, the Klik Lighting Control Module (LCM) offers a flexible and easy plug-and-play solution for applications where multi-channel control is required. Typical applications include classrooms, meeting rooms and individual office space.

The four-channel Klik LCM offers auto-dimming control through the KlikLink® Occupancy sensors. Where there is an abundance of natural light, the integrated light sensor input is used to dim digital luminaires and, in turn, reduce energy use. The LCM gives the user the ability to dim or switch off rows of luminaries when using equipment such as an interactive whiteboard or projector. The LCM also offers multi-point safety extra low voltage switching, which negates the need for residual current device (RCD) protection where there are switch drops. Programmed using the KlikLink® iPad App via Bluetooth, lighting setup couldn’t be easier.

Some applications require a wider range of building control options, so the integration of our Tebis KNX building automation is a logical step to offer numerous possibilities to control other outputs such as blinds, shutters, heating and energy monitoring.

On larger projects, we are aware that lighting distribution design can be a mammoth task for consultants and contractors, so to meet these demands we’ve developed the Klik Project Design Service, offering fully calculated lighting distribution designs, including detailed drawings and delivery schedules to individual project requirements. These applications are where full compliance to BS 8488:2009+A1:2010 is specified (pre-fabricated wiring system intended for permanent connection in fixed installations).

Some applications require a wider range of building control options, so the integration of our Tebis KNX building automation is a logical step to offer numerous possibilities to control other outputs such as blinds, shutters, heating and energy monitoring.

On larger projects, we are aware that lighting distribution design can be a mammoth task for consultants and contractors, so to meet these demands we’ve developed the Klik Project Design Service, offering fully calculated lighting distribution designs, including detailed drawings and delivery schedules to individual project requirements. These applications are where full compliance to BS 8488:2009+A1:2010 is specified (pre-fabricated wiring system intended for permanent connection in fixed installations).